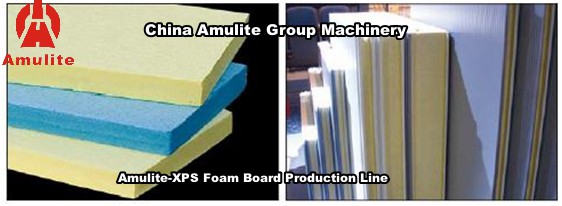

Amulite CO2 XPS Foomu Board Production Line

Apejuwe kukuru:

I.Technical Introduction

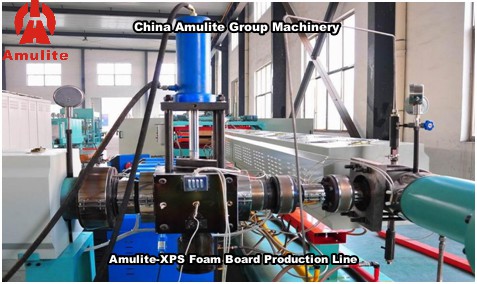

Ni akọkọ, compounding symmetrical1y XPS ohun elo pẹlu awọn ohun elo oluranlọwọ miiran bi oluranlowo iparun ati ipele awọ; Ni keji fi wọn sinu hopper ti Grade Iextruder nipasẹ atokan igbale automatical1y; yo ni kẹta ati plasticizing resin byspecial1y apẹrẹ dabaru symmetrically, ni akoko kanna abẹrẹ oluranlowo foomu nipasẹ titẹ giga ati dapọ o pẹlu yo o resini; Fourthly, fifi wọn sinu ite IIextrusion eto lati pade, illa, fi titẹ ati ki o dara lẹẹkansi ati extruding foomu boardby pataki m fun ọkọ, ki o si itutu ati lara ọkọ nipa itutu ati formingdexiss..kifthly.fifi awọn ọkọ sinu ite I fa-pipa eto ati gbigbe theminto ite Il fa-pipa eto nipa transportation rol1s;Ni kẹfa, gige egbin eti bysaw ti ẹgbẹ mejeeji ati ipari gige iṣipopada ni ibamu si ṣeto 1ength;awọn 1st igbese, stacking ati ibi ipamọ.

Alaye ọja

ọja Tags

Ina Unit:

Moto Beide Brand akọkọ (Siemens Standard Motors Ltd.)

Oluyipada Danfoss tabi Siemens Brand

AC Contactor Siemens tabi Schneider Brand oluṣakoso iwọn otutu mita Omron Brand tabi Fuji Brand Foliteji 380V, 50HZ

AM-XPS75P/200 CO2XPS Foomu Board Production Line

I.Imọ-ẹrọal Ifaara

Ni akọkọ, idapọ awọn ohun elo XPS symmetrically pẹlu awọn ohun elo oluranlọwọ miiran bii aṣoju iparun ati ipele awọ;Ẹlẹẹkeji fi wọn sinu hopper ti Ite I extruder nipasẹ igbale atokan laifọwọyi;Thirdly yo ati plasticizing resini nipa Pataki ti a še dabaru symmetrically, ni akoko kanna abẹrẹ foomu oluranlowo nipa ga titẹ ati ki o dapọ o pẹlu yo o resini;Ni ẹkẹrin, fifi wọn sinu eto extrusion Grade II lati yo, dapọ, ṣafikun titẹ ati dara lẹẹkansi ati fifa ọkọ foomu nipasẹ apẹrẹ pataki fun igbimọ, lẹhinna itutu agbaiye ati igbimọ nipasẹ itutu agbaiye ati ẹrọ gbigbẹ; karun, fifi ọkọ sinu Ite I fa- pa eto ati gbigbe wọn

sinu ite II fa-pipa eto nipa gbigbe yipo;Kẹfa, gige egbin eti nipa

ri ti awọn mejeeji-ẹgbẹ ati finishing ifa gige ni ibamu si ṣeto ipari;awọn ti o kẹhin igbese, stacking ati ibi ipamọ.

II.Awọn Akọkọ Ohun elo

1> XPS resini

2> Aṣoju Foam & Iranlọwọ oluranlowo foam 3> Aṣoju iparun

4> Awọ ipele

5> Awọn ohun elo iranlọwọ miiran

Akiyesi: A yoo pese awọn onibara wa pẹlu iwe ilana oogun, iru ohun elo ati awọn iwe imọ-ẹrọ ibatan lẹhin ti fowo si iwe adehun.

Ẹrọ Ẹya

1> Ṣiṣu aladapo 1 ṣeto

2> Ite Mo extrusion eto 1 ṣeto

3> CO2Eto abẹrẹ oluranlowo foomu 1 ṣeto 4> Eto abẹrẹ oluranlowo foam oluranlowo 1 ṣeto 5> CO2Eto ifihan ṣiṣan 1 ṣeto 6> Eto abẹrẹ aṣoju Foam HCFC 1 ṣeto 7> Eto paṣipaarọ apapọ aifọwọyi 1 ṣeto

8> Ite II extrusion eto 1 ṣeto

9> Extrusion kú ori 1 ṣeto

10> Calibrating ati fa-pipa eto 1 ṣeto

11> Gbigbe ati itutu eto 1 ṣeto

12> Ite II fa-pipa eto 1 ṣeto

13> Lengthways gige eto 1 ṣeto

14> Petele Ige eto 1 ṣeto

AM-75P/200 CO2XPS Foamed Board Production Line

1.Ifunni eto

2.AM75/44Twin-skru extruder 1 ṣeto

3.CO2foomu oluranlowo abẹrẹ system1 ṣeto

4.Iranlọwọ foomu oluranlowo abẹrẹ eto 1 ṣeto

5.Eto abẹrẹ aṣoju Foam Freon 1 ṣeto

6.CO2sisan ifihan eto 1 ṣeto

7.Laifọwọyi net-paṣipaarọ eto 1 ṣeto

8.Ipele II extrusion eto 1 ṣeto

9.Extrusion kú ori 1 ṣeto

10.Eto iwọntunwọnsi ati yiyọ kuro 1 ṣeto

11.Eto gbigbe ati itutu agbaiye 1 ṣeto

12.Ipele II fa-pipa eto 1 ṣeto

13.Awọn ọna gigun gige eto 1 ṣeto

14.Petele gige eto 1 ṣeto

15> Iyipada gige eto 1 ṣeto

15.Ina kuro

XPS Foamed Board atunlo ati Pelletizer Machine

Awoṣe AM-XPS-JR100B

1> XPS foomu ọkọ crusher ẹrọ 1 ṣeto

2> Nikan dabaru plasticizing ati extrusion ẹrọ 1 ṣeto

3> Ajọ net-iyipada ẹrọ 1 ṣeto

4> Itutu agbaiye ojò 1 ṣeto

5> Ige pellet ẹrọ 1 ṣeto

Akiyesi: Iwọn ti o wa loke ti aṣoju foomu jẹ fun itọkasi rẹ nikan, a ṣe atunṣe data gangan ni ibamu si ibeere ti ohun elo aise ati ọja.